Description

Bushes according to OST 1 11121-73 – made of brass L63 and LS59-1.

Description

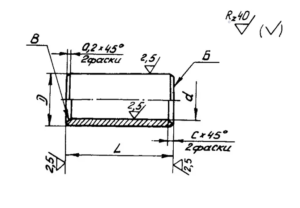

OST 1 11121-73 Bushings for pressing in

Bushes according to OST 1 11121-73 – made of brass L63 and LS59-1.

Description of product design features

Installation bushings must be produced in four versions, depending on the maximum deviations for the inner diameter:

- performance 1 – by H7;

- performance 2 – by H9;

- version 3 – by H12;

- performance 4 – by M7.

Three radial marks with a depth of 0.2 – 0.3 mm.

Coating bushings for pressing with cadmium (Kd3.xp) is carried out in our own electroplating shop.

An example of the name and designation of a bushing for pressing version 1 with dimensions d = 8 mm, D = 10 mm and L = 25 mm made of brass, coated Kd3.xr:

Sleeve 1-8-10-25-Kd-OST 1 11121-73

Product applications

The most popular bushings are in mechanical engineering, automotive and aircraft manufacturing. Without them, the work of transport and production machines will simply be impossible. After all, I am located between two moving elements, they are reliable protection for each of them. Therefore, the bushings themselves must be plastic and durable.

The use of bushings allows during the operation of a mechanism to carry out a planned replacement of the element itself. At the same time, if the operating conditions and regular maintenance are observed, the replacement of expensive parts of the product or its body will not be required. The bushings themselves are often consumables that allow the operation of large components and assemblies.